FLOATING FORGED STEEL BALL VALVE

- Design Basis: API 6D/BS 5351/API 608

- Structure Length: ASME B16.10

- Flange Size: ASME B16.5

- Test and Inspection: API 598

Floating forged steel ball valves are commonly used in a variety of industrial applications, including oil and gas, petrochemical, chemical, power generation, and water treatment industries. They are designed to provide reliable and long-lasting performance in high-pressure and high-temperature environments, making them ideal for critical applications where safety and reliability are important. Some common applications for floating forged steel ball valves include pipeline transportation, oil and gas refining, chemical processing, and power plant operations. The main difference between floating cast steel ball valves and floating forged steel ball valves is the manufacturing process, with forged steel ball valves being made from a solid piece of metal that is hammered and shaped into its final form, while cast steel ball valves are made by pouring molten metal into a mold.

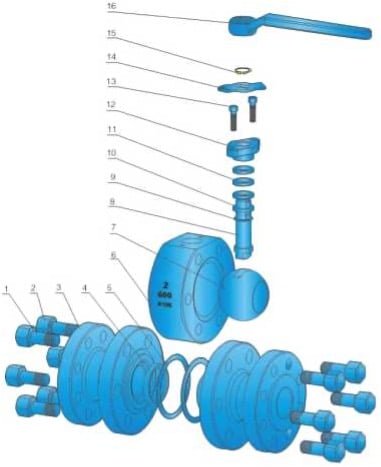

MATERIAL TABLE OF MAIN PARTS

No. | Part Name | Material |

ASTM | ||

1 | Gasket | Flexible Graphite + Stainless Steel |

2 | Seat | PTFE |

3 | Right body | A105 |

4 | Nut | A194-2H |

5 | Stud | A193-B7 |

6 | Body | A105 |

7 | Ball* | A105+ENP |

8 | Stem** | A182-F6a |

9 | Gasket | PTFE |

10 | Padding | A276-410 |

11 | Packing | Flexible Graphite |

12 | Packing gland | A216-WCB |

13 | Bolt | A193-B7 |

14 | Positioning pieces | Carbon steel |

15 | Retaining ring | Al SI 1566 |

16 | Handle | A47-66732510 |

Request a FREE quote

we look forward to collaborating with you.