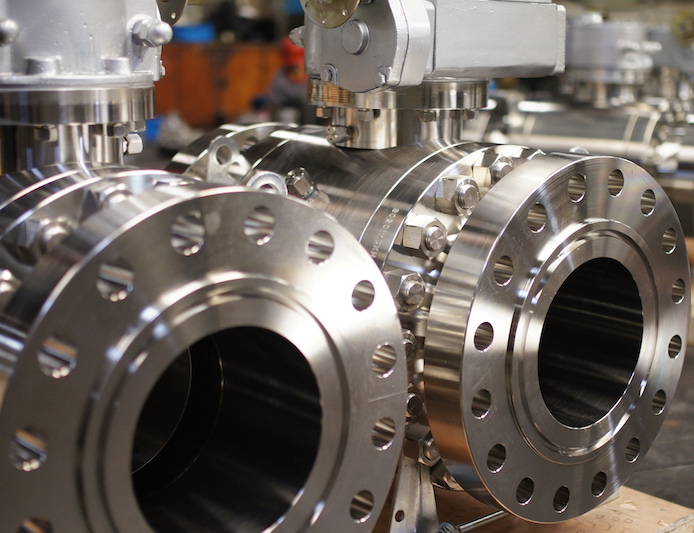

TRUNNION MOUNTED BALL VALVE

Trunnion mounted ball valves are commonly used in industrial applications where high pressure, high temperature, and large diameter pipelines are involved. Some of the applications where trunnion mounted ball valves are used include oil and gas, petrochemical, chemical, power generation, and water treatment industries.

The trunnion mounted ball valve design provides additional support to the ball, which reduces the torque required to operate the valve. This makes it suitable for high-pressure applications where the valve needs to be operated frequently. The valve also has a floating seat design, which ensures a tight seal even at high pressures.

The trunnion mounted ball valve is also designed to withstand harsh environments and extreme temperatures, making it ideal for use in industries that deal with corrosive or abrasive materials. Additionally, the valve can be automated, making it easy to operate and control remotely.

Forged Steel Trunnion Mounted Ball Valve

Cast Steel Trunnion Mounted Ball Valve

Trunnion mounted ball valve

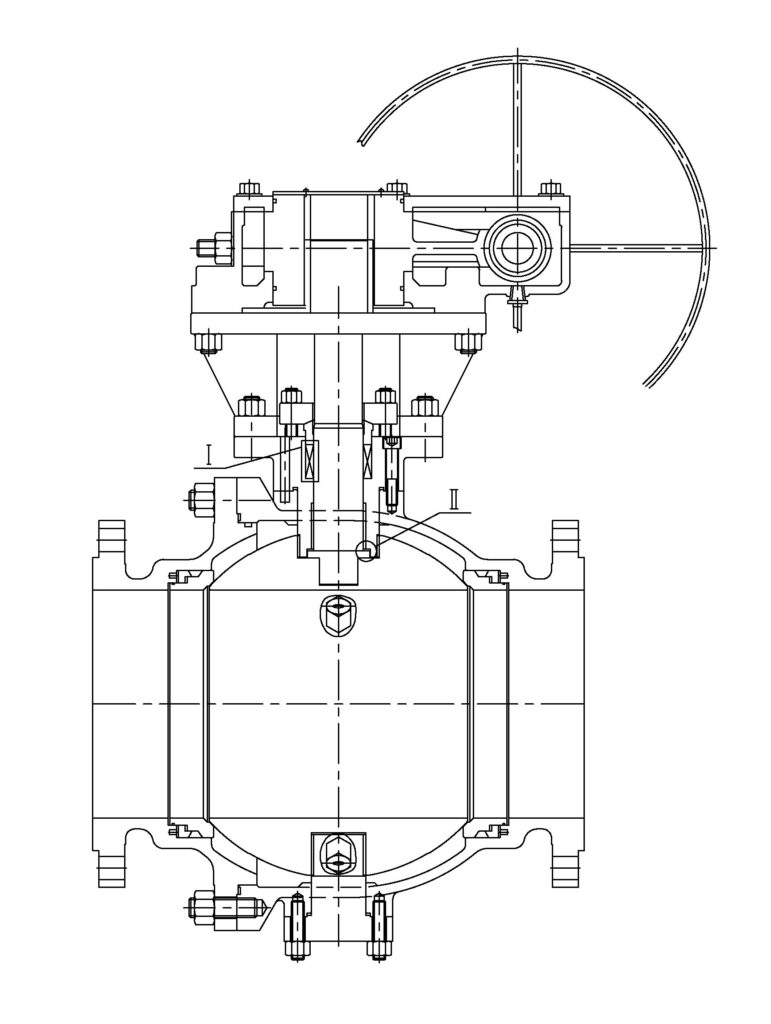

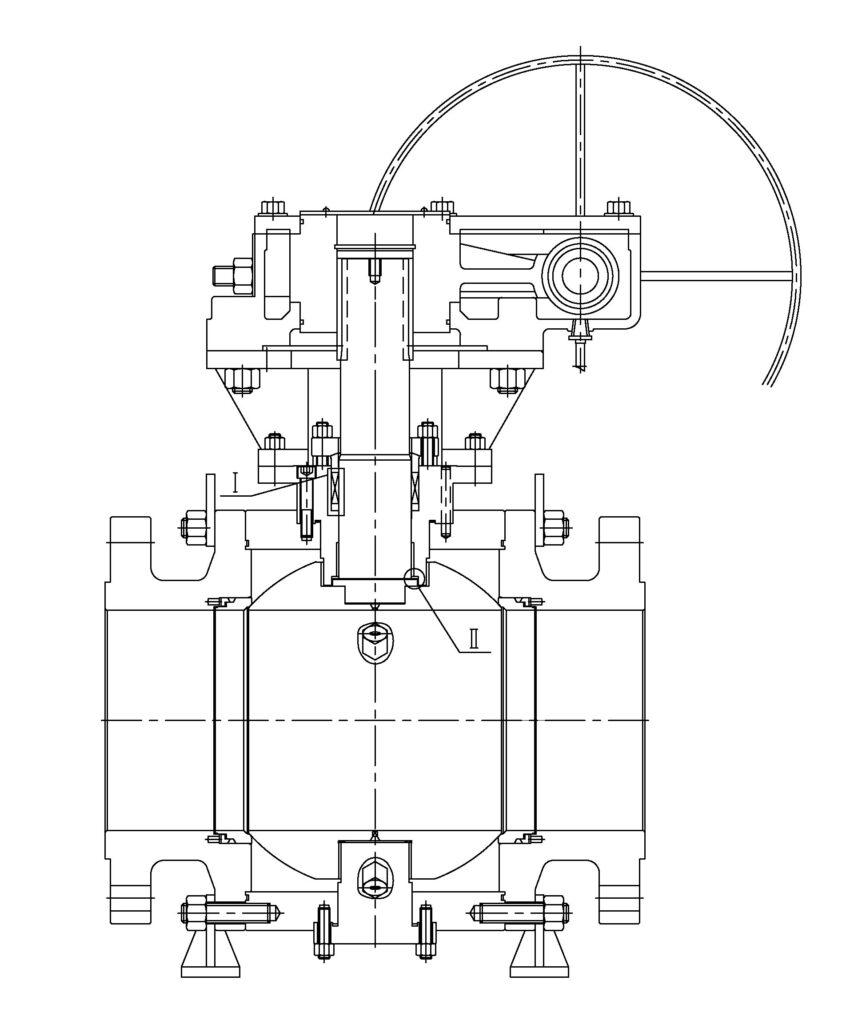

STRUCTURE FEATURES

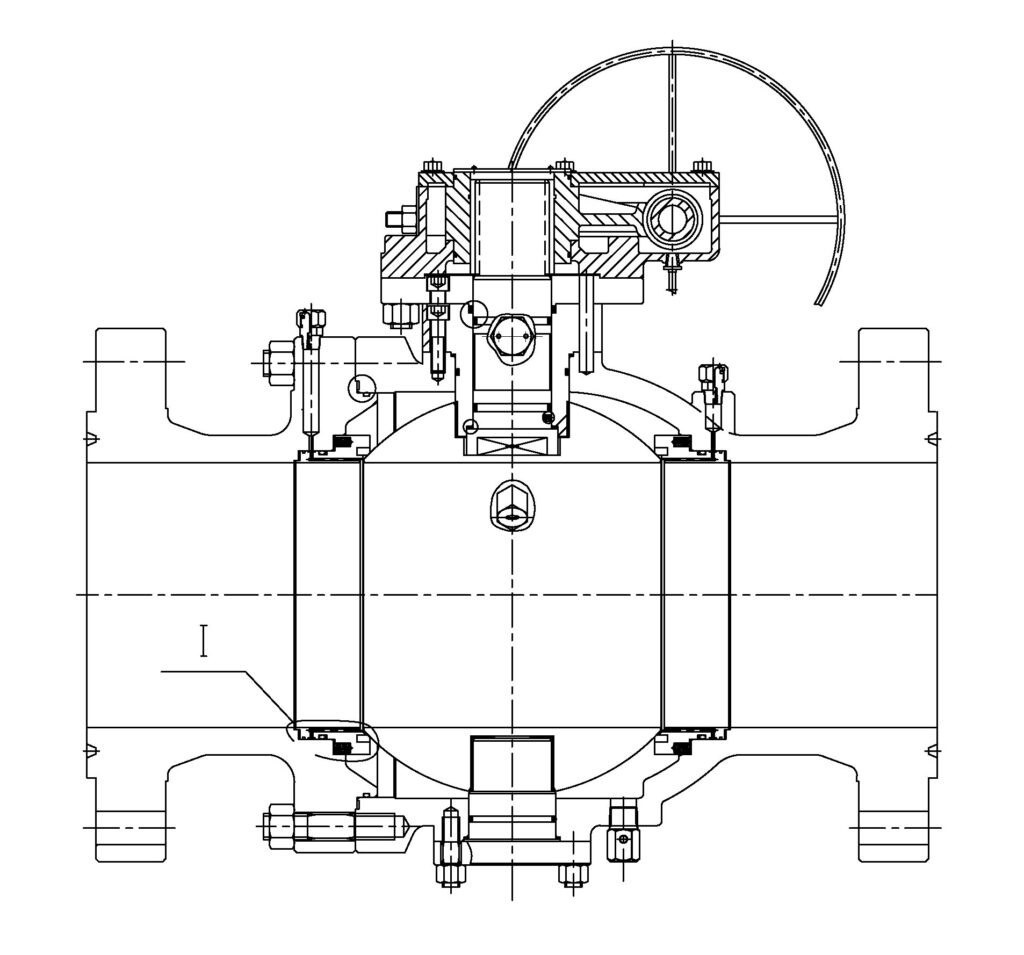

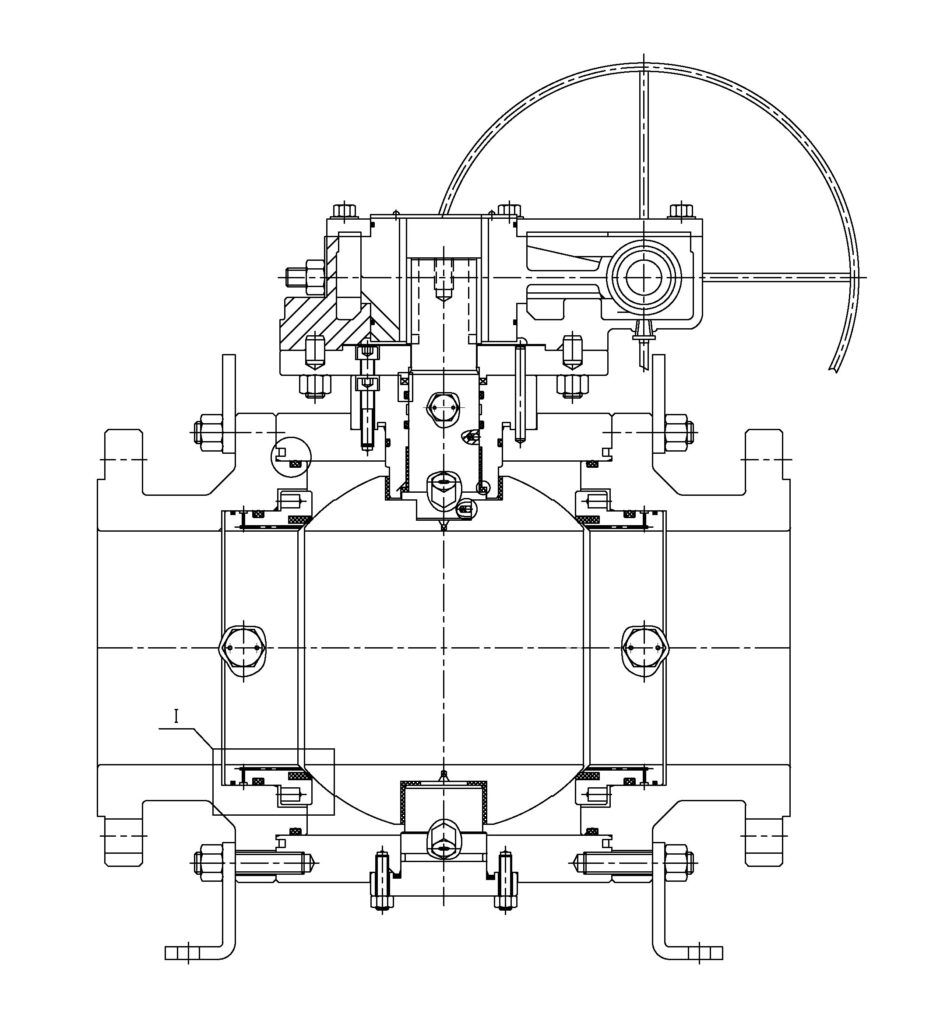

Trunnion Mounted Ball Valve Hard Seat Type

| Part Name | Material for cast steel | Material for forged steel |

| Body | WCB / LCB / CF8 / CF8M | A105 / LF2 / F304 / F316 |

| Bonnet | WCB / LCB / CF8 / CF8M | A105 / LF2 / F304 / F316 |

| Ball | A105 / LF2 / F304 / F316+STL / Ni60 / TCC | |

| Seat | A105 / LF2 / F304 / F316+STL / Ni60 / TCC | |

| Stem | F6a / F304 / F316 / F51 / 17-4PH | |

| Lower Stem | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seal Sleeve | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Support | CS | |

| Stud | B7 / L7 / B8 / B8M | |

| Nut | 2H / 7 / 8 / 8M | |

| Seat Seal | Flexible Graphite | |

| Gasket | SS304 + Graphite / SS316 + Graphite | |

| Packing | Flexible Graphite | |

| Drain Valve | CS +Zn / SS304 / SS316 | |

| Release Vavle | CS +Zn / SS304 / SS316 | |

| Worm Gear | Assembly | |

Cast Steel

Forged Steel

Trunnion Mounted Ball Valve Soft Seat Type

| Part Name | Material for cast | Material for forged |

| Body | WCB / LCB / CF8 / CF8M | A105 / LF2 / F304 / F316 |

| Bonnet | WCB / LCB / CF8 / CF8M | A105 / LF2 / F304 / F316 |

| Ball | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seat | PTFE / RPTFE / DEVLON / PEEK | |

| Seat Retainer | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stem | F6a / F304 / F316 / F51 / 17-4PH | |

| Lower Stem | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seal Sleeve | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stud | B7 / L7 / B8 / B8M | |

| Nut | 2H / 7 / 8 / 8M | |

| O-Ring | VITON AED / HNBR AED | |

| Anti Fire Ring | Flexible Graphite | |

| Anti Static Device | SS316 | |

| Gasket | SS304 + Graphite / SS316 + Graphite | |

| Packing | Flexible Graphite | |

| Drain Valve | CS +Zn / SS304 / SS316 | |

| Release Valve | CS +Zn / SS304 / SS316 | |

| Worm Gear | Assembly | |

Cast Steel

Forged Steel

Request a FREE quote

we look forward to collaborating with you.