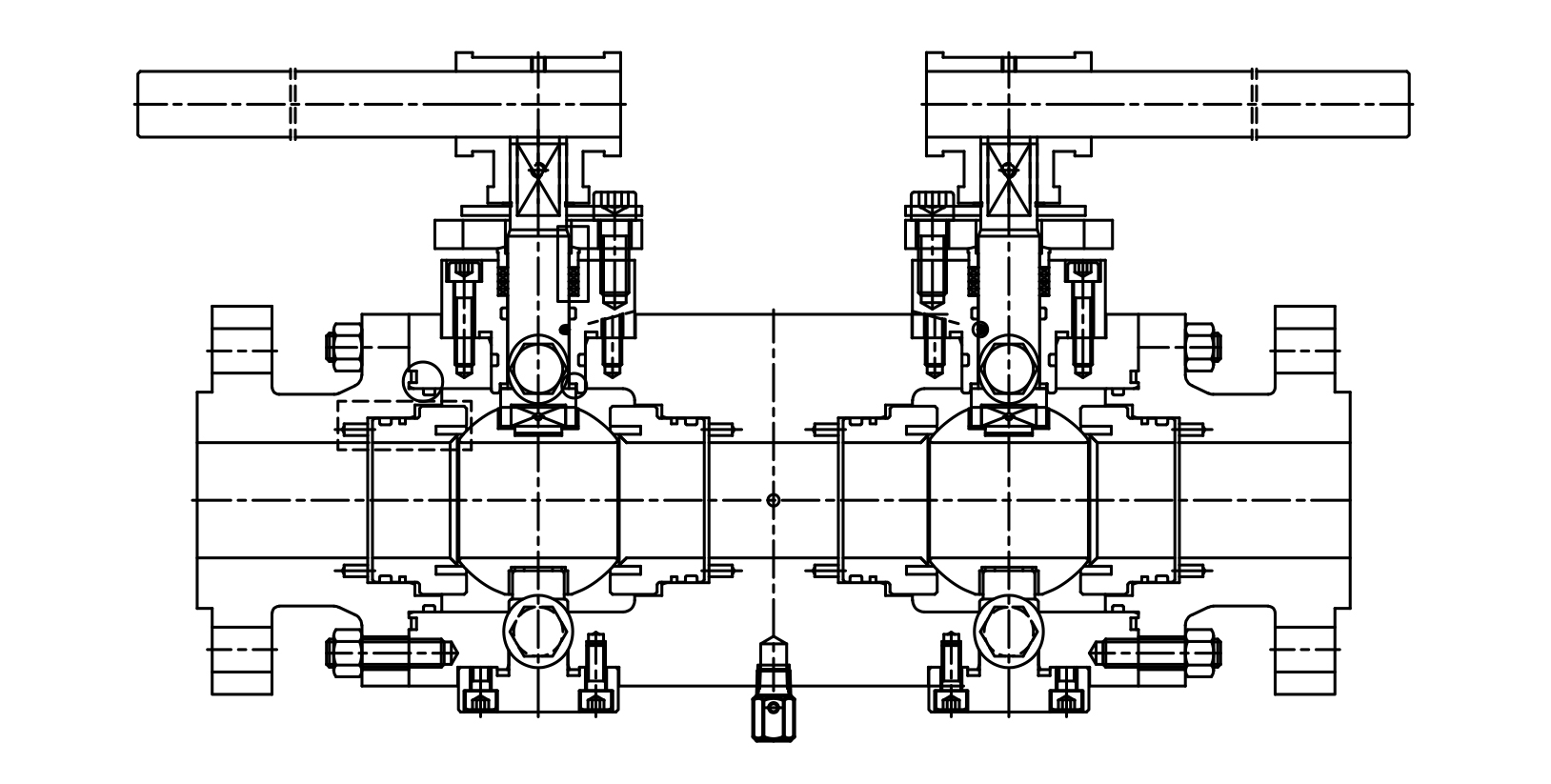

DBB Ball Valve

Double block and bleed valves, or DBB ball valves, are specialized ball valves that provide double isolation and bleeding capabilities. They contain two ball valves with a bleed valve in between. The ball valves isolate the upstream and downstream sections of the pipeline, while the bleed valve releases any trapped fluid between the valves.

DBB valves are used when performing maintenance on a pipeline section. The two ball valves are closed to isolate the target section, then the bleed valve is opened to depressurize it by draining the trapped fluid. This ensures the safe and environmentally compliant isolation of the pipeline.

DBB valves provide extra assurance of zero leakage compared to single valves. For any flow to occur, both ball valves would have to fail, which is highly unlikely if the valves are properly selected and tested. The ball valves allow quick shutoff and re-opening with 90-degree turns.

DBB valves are used in oil & gas, chemical and other industries that require frequent operations on live pipelines. They maximize safety, environmental protection and uptime. DBB valves come in various types like 3-way (2 ball valves and 1 bleed) or 4-way (2 ball valves and 2 bleeds) configurations. Sizes, pressure ratings, and ends like flanged or threaded are chosen based on application needs. Manual or automated operation is available depending on the required level of control and integration.

In summary, DBB ball valves provide the vital functions of double isolation, bleeding, and de-pressurization required to safely perform work on live pressurized pipelines while mitigating environmental and safety hazards. They come in a wide range with many options to suit application needs. Overall, DBB ball valves are an indispensable tool for industries that manage hazardous fluids and gases.

DBB Ball valve

STRUCTURE FEATURES

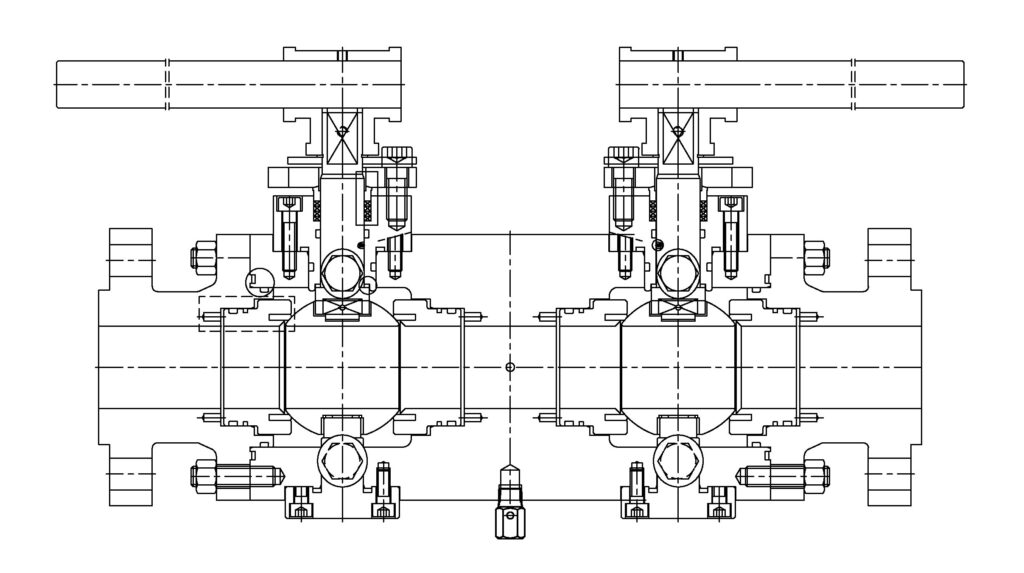

The Trunnion mounted ball valve adopts a spring-preloaded floating soft-seated structure so that regardless of whether the valve is fully open or closed state; both upstream/downstream sides will block fluid flow while allowing trapped substances inside cavity between valves body through discharge valves.

When there's abnormal increase in temperature due to medium retention within cavity between valves body which causes abnormal rise in pressure; automatic relief can be achieved solely through functional capabilities of seating instead of relying on safety valves alone - this feature ensures safe transport during liquid delivery.

All gate bodies possess fire-resistant functionality designed & manufactured according API 607 specifications requirements.

Both upper/lower parts of gate body have discharge holes which allow inspection if leakage occurs at adjustable seats; during operation when gate body is fully open or closed position - middle chamber pressure can be released directly by replacing packing materials or discharging trapped substances inside cavity reducing pollution caused by medium against gates.

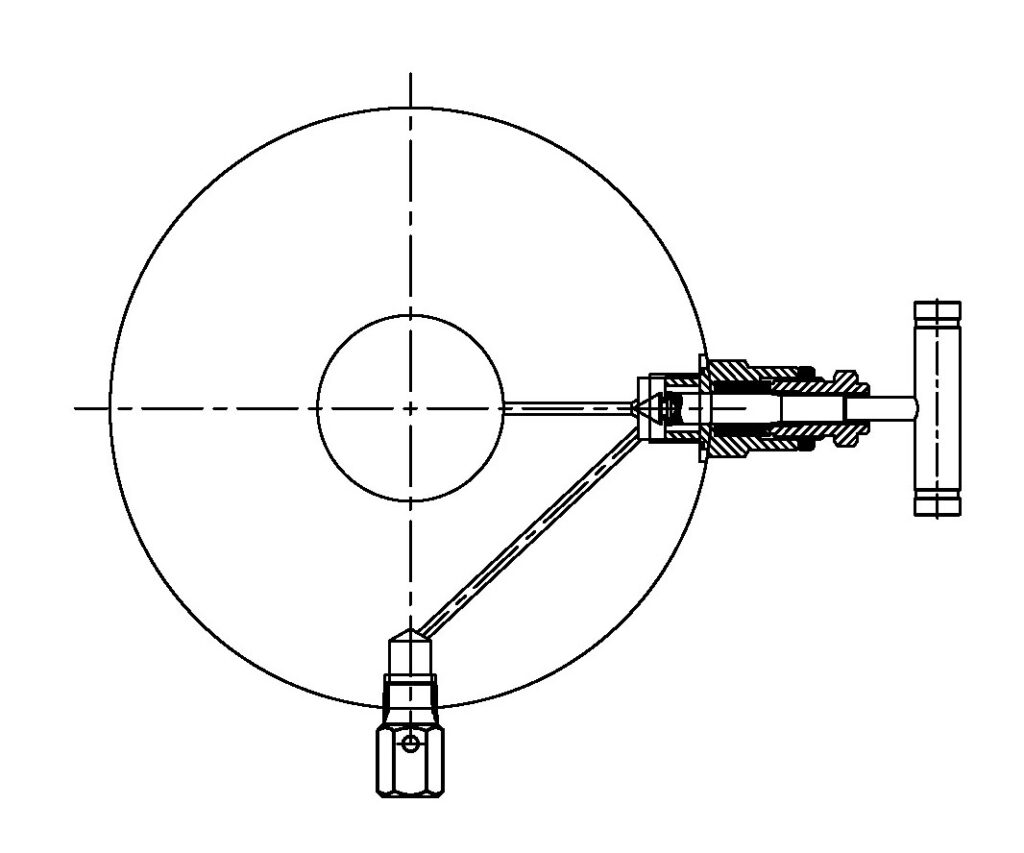

A needle-shaped sampling interface connected with with drain valves has been set up at midpoint location making it easy for monitoring pipeline internal media conditions

Material for Main Parts

| Part Name | Material for cast steel | Material for forged steel |

| Body | A105 / LF2 / F304 / F316 | |

| Bonnet | A105 / LF2 / F304 / F316 | |

| Ball | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seat | PTFE / RPTFE / DEVLON / PEEK | |

| Seat Retainer | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stem | F6a / F304 / F316 / F51 / 17-4PH | |

| Lower Stem | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seal Sleeve | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stud | B7 / L7 / B8 / B8M | |

| Nut | 2H / 7 / 8 / 8M | |

| O-Ring | VITON AED / HNBR AED | |

| Anti Fire Ring | Flexible Graphite | |

| Anti Static Device | SS316 | |

| Gasket | SS304 + Graphite / SS316 + Graphite | |

| Packing | Flexible Graphite | |

| Drain Valve | CS +Zn / SS304 / SS316 | |

| Release Valve | CS +Zn / SS304 / SS316 | |

| Worm Gear | Assembly | |

Front View

Side View

Request a FREE quote

we look forward to collaborating with you.