Grease Fitting

Grease Fittings are installed onto the seat and stem of valves. Leakage may occur when the sealed part wears off or for other reasons.

The leakage will be sealed temporarily by injecting the grease through the grease fitting to secure time for remedial measures.

These specialized fittings serve as emergency sealing solutions, allowing operators to maintain system operation while planning comprehensive repairs.

The grease injection process creates a temporary barrier that prevents fluid loss and maintains pressure integrity. Commonly featuring standard Zerk or button-head designs, these fittings accommodate various grease gun attachments for easy field application.

The injected grease fills microscopic gaps and surface irregularities that develop over time due to thermal cycling, mechanical wear, or chemical degradation.

This temporary sealing method is particularly valuable in critical applications where immediate shutdown would result in significant operational losses.

Proper grease selection ensures compatibility with system fluids and operating temperatures for optimal sealing effectiveness.

Grease Fitting

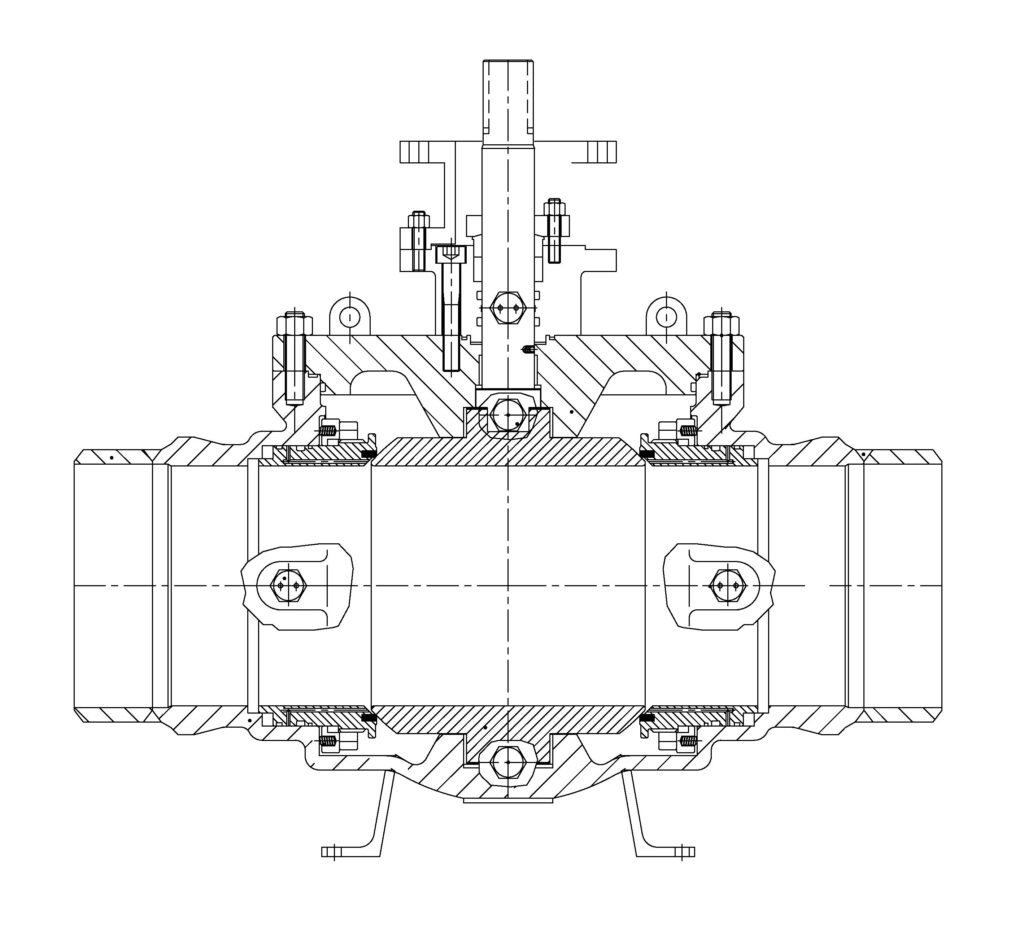

STRUCTURAL FEATURES

Specs for Top Entry Ball Valve

| Specifications | API series |

| Design specification | API 6D, API 608, BS5351 |

| Press u re temperature rating | ASME B16.34 |

| Structuial length | ASME B16.10 |

| Flange connection | ASME B16.5, ASME 16.47 |

| Butt welding end connection | ASME B16.25 |

| Inspection and testing | API 598, API 6D |

| Fire test | API 6FA |

| Steel casting quality inspection | MSS-SP-55 |

Request a FREE quote

we look forward to collaborating with you.