Pigging Valve

The pigging valve is a new type of valve primarily used for cleaning long-distance pipelines carrying water, oil, natural gas, and other mediums. It facilitates the launch and reception of the pig, which is used for cleaning the pipeline. By using the appropriate pig, the valve can easily clean, empty, and isolate the pipeline, as well as transport the medium in an orderly manner and test the pipeline system. The pigging valve can completely replace the traditionally used and complex pig transmitting and receiving devices, with the pig transceiver as the core.

The pigging valve is innovatively designed based on the structural principle of the fixed ball valve, with modifications and additional functions. It inherits the performance characteristics of the two-position cut-off ball valve and can be opened and closed through a 90-degree rotation of the ball core. The valve can be designed as a double block, meaning it can discharge the medium in the body cavity when it is fully open or fully closed. This function is necessary for pigging valves.

A branch pipe is opened on the side of the valve body, with the branch pipe center intersecting the pipeline center perpendicularly. A quick-open blind plate and a vent valve are installed on the branch pipe, making it easy to feed the pig into or take it out of the pig valve. The diameter of the ball through hole is larger, and one end of the through hole can prevent the pig from passing through. A barrier allows the medium to circulate.

The pigging valve undergoes a 100% pressure test to ensure that there is no visible leakage in any sealing parts. It has a fire-resistant safety design, and when the elastic valve seat is burned, a metal-to-metal seal is formed between the ball and the valve seat. The valve body bonnet and valve stem are all set with high-temperature-resistant graphite gaskets to ensure high-temperature sealing reliability. The fire resistance test meets the requirements of API 6FA and API 607. The valve also has an antistatic design, with a static conductive spring that ensures good conduction between the ball and the valve body, as well as the valve stem and the valve body. This design leads out static electricity generated by friction.

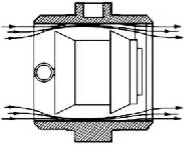

Standard Pigging Valve Type C

Type C is a standard pigging valve for pipe cleaning.

Its spherical hole area is about 25% larger than the pipe flow area to ensure the continuous flow of the conveying medium during the pigging operation.

Type C pigging valve can be used as a shut-off valve.

Performance characteristics:

1. The valve stem is not affected by the thrust of the ball, the valve stem can be twisted freely, and the valve operation is flexible

2. The quick opening blind plate is easy to operate

3. Zero leakage

4. Interlocking design ensures the safety of operators

5. Fire-resistant safety design fire-resistant test meets the requirements of API 6FA and API 607 standards

6. Antistatic design

7. Cleaning design

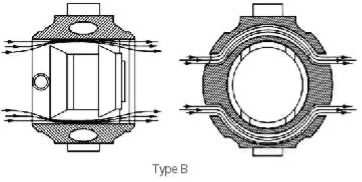

Bypass Pigging Model Type B

Type B is a pigging valve with bypass.

Two elliptical passages are opened on the sphere perpendicular to the direction of the ball hole, and the flow area is about 25% of the pipe.

This structure ensures that the pig valve will not be cut off even when the pig is transmitted or received.

B-type pigging valve cannot be used as a shut-off valve.

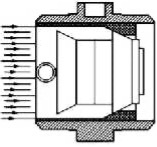

Isolated Pigging Valve Model Type S

S-type pigging valve is mainly used for isolating and sequentially conveying medium.

Its ball hole area is about 3% larger than the pipe flow area, and there is an additional seal in the ball hole of the receiving pig valve to ensure that the isolation pig reaches the receiving pig valve to form a seal and obtain an ideal isolation effect.

The S-type pig valve can be used as a shut-off valve.

pigging valve

STRUCTURE FEATURES

1. The valve stem is not affected by the thrust of the ball, the valve stem can be twisted freely, and the valve operation is flexible

2. The quick opening blind plate is easy to operate

3. Zero leakage

4. Inter locking design ensures the safety of operators

5. Fire-resistant safety design, fire-resistant test meets the requirements of API SFAandAPI 607 standards

6. Antistatic design;

7. Cleaning design.

Design and manufacture according to: API 6D GB/T12237-2009

Test and inspection according to: API 598 JB/T9092-2009

Flange size according to: ANSI B16.5 GB/T 9113-2009; JB/T79-2007 HG20592-2009

Structure length according to: CTV-2000

The valve adopts carbon steel and low temperature steel as the main material for oil and gas transportation conditions, and is divided into ordinary and sulfur resistantseries.

The anti-sulfur valve material complies with the regulations of NACE MR01-75.

The suitable temperature for carbon steel series is -29 - 150 °C and the suitable temperature for lowtemperaturesteel series is -46 - 121 °C.

Material for Main Parts

| Part Name | Material for cast steel | Material for forged steel |

| Body | A105 / LF2 / F304 / F316 | |

| Bonnet | A105 / LF2 / F304 / F316 | |

| Ball | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seat | PTFE / RPTFE / DEVLON / PEEK | |

| Seat Retainer | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stem | F6a / F304 / F316 / F51 / 17-4PH | |

| Lower Stem | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Seal Sleeve | A105 + ENP / LF2 + ENP / F304 / F316 | |

| Stud | B7 / L7 / B8 / B8M | |

| Nut | 2H / 7 / 8 / 8M | |

| O-Ring | VITON AED / HNBR AED | |

| Anti Fire Ring | Flexible Graphite | |

| Anti Static Device | SS316 | |

| Gasket | SS304 + Graphite / SS316 + Graphite | |

| Packing | Flexible Graphite | |

| Drain Valve | CS +Zn / SS304 / SS316 | |

| Release Valve | CS +Zn / SS304 / SS316 | |

| Seal and Fitting | CS +Zn / SS304 / SS316 | |

| Quick opening device | A105 / LF2 / F304 / F316 | |

| Pressure Gage | Assembly | |

| Worm Gear | Assembly | |

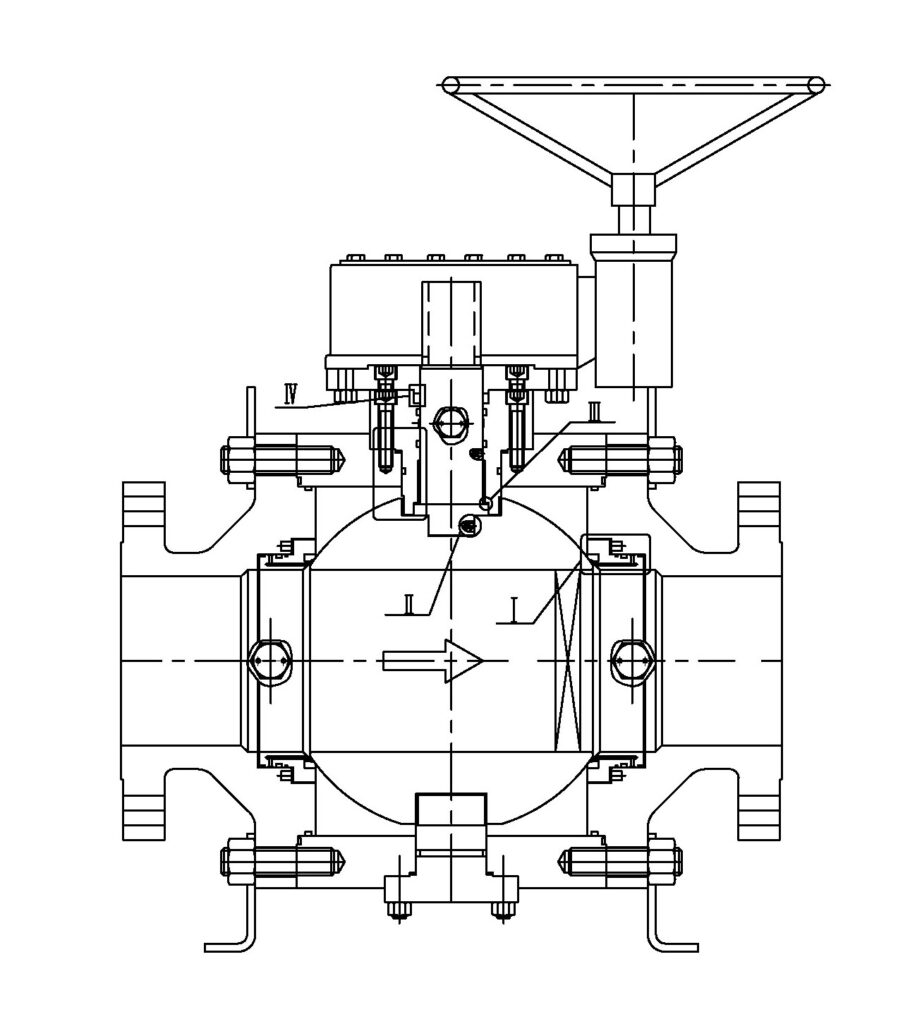

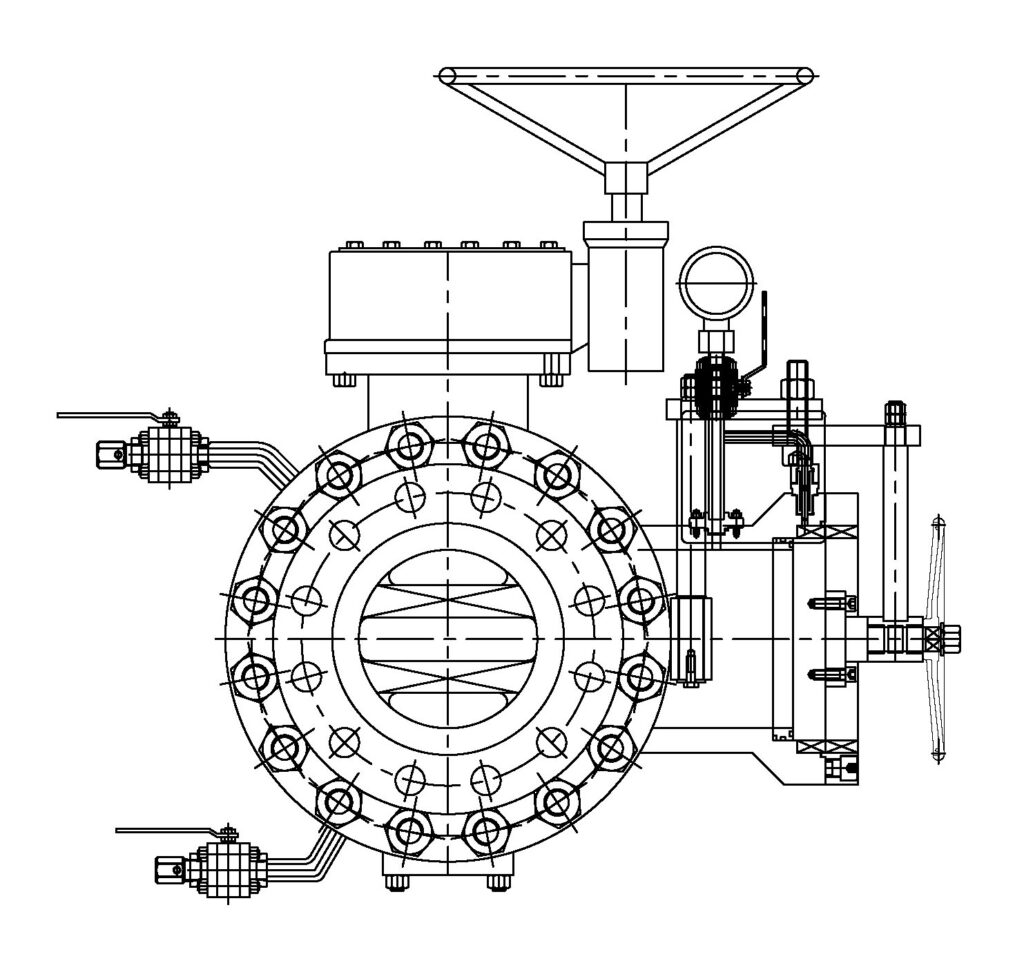

Pigging Valve Front View

Pigging Valve Side View

Request a FREE quote

we look forward to collaborating with you.